By Doyle Sumrall, NTEA Managing Director

This article was published in the April 2017 edition of NTEA News.

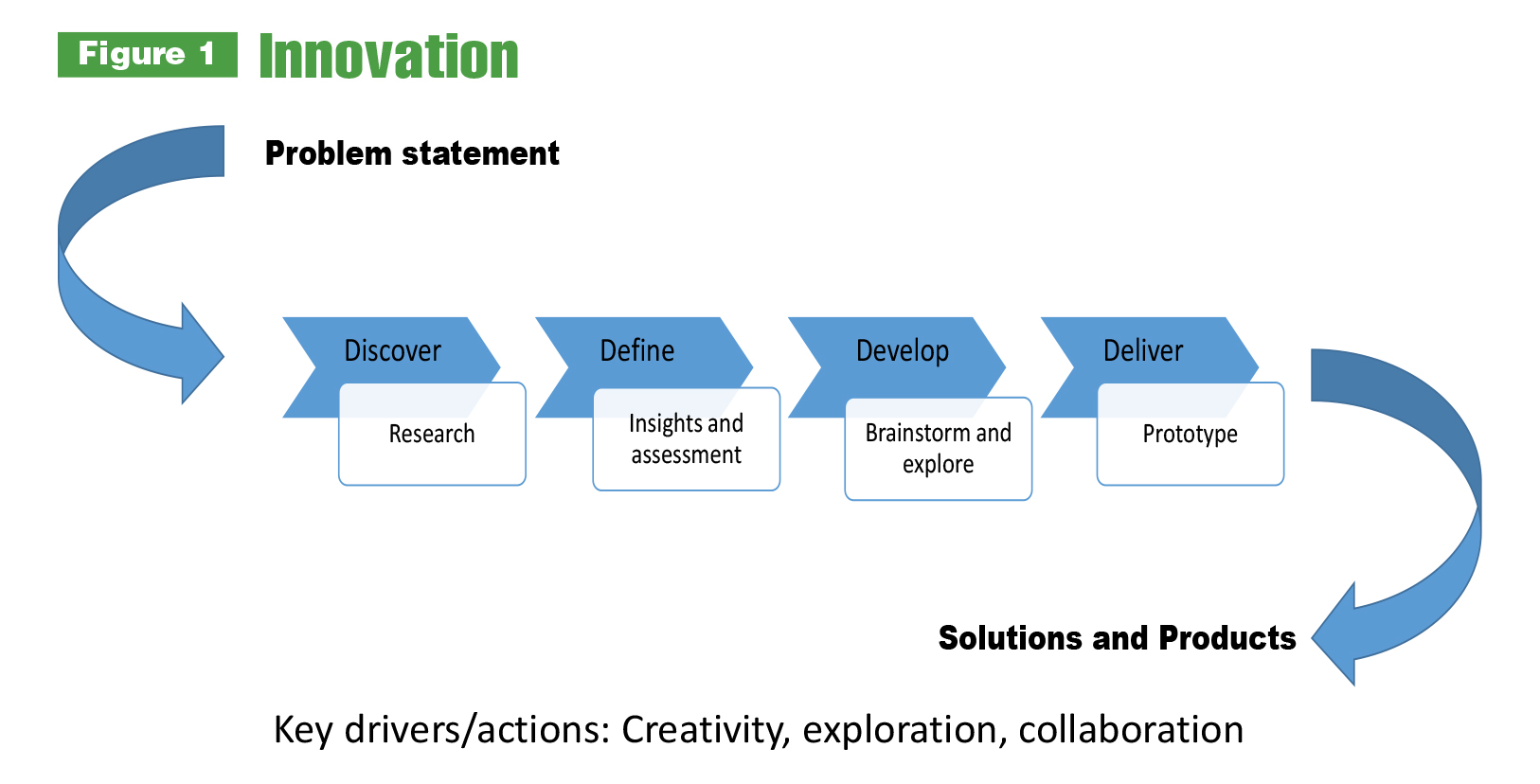

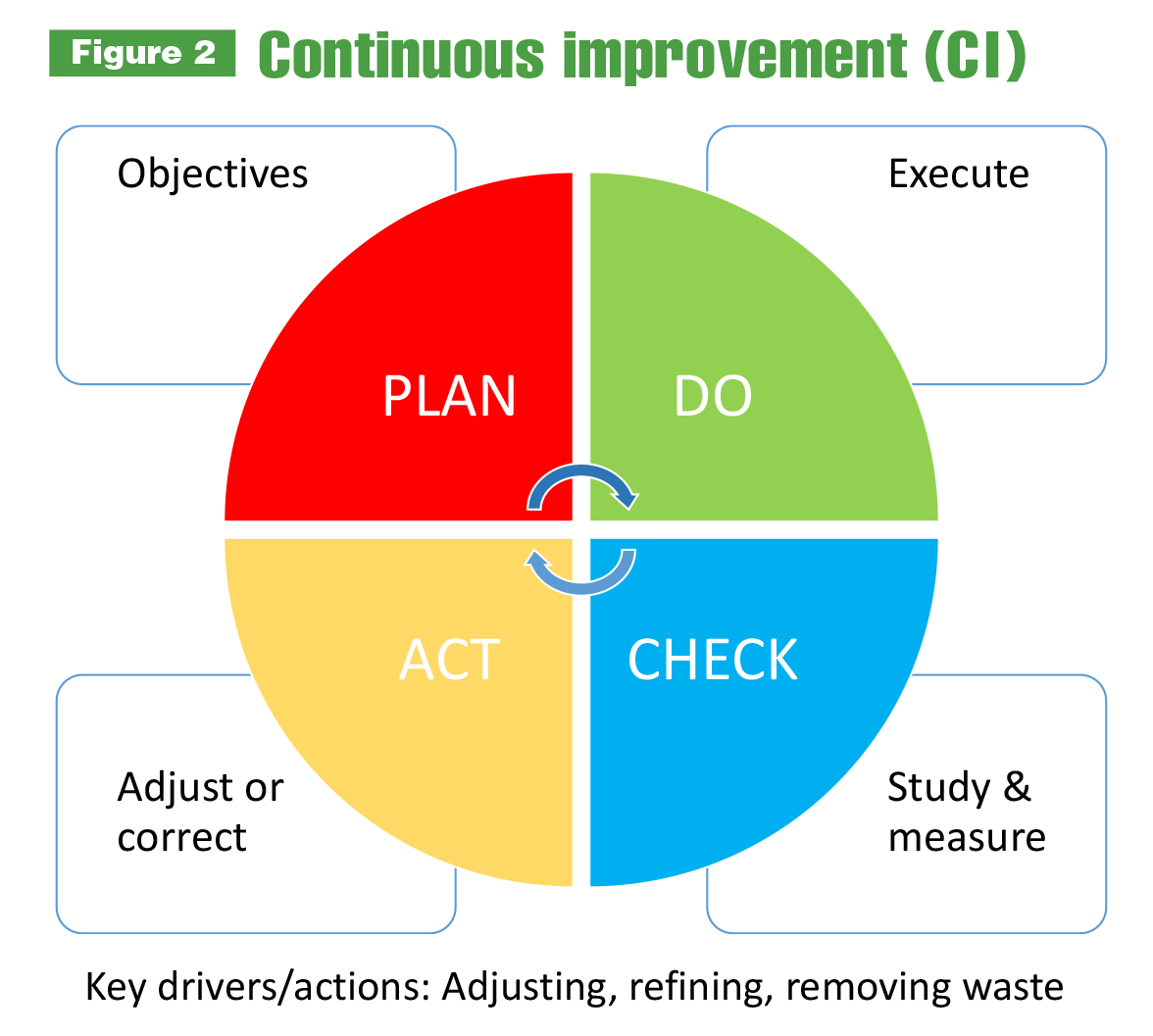

Most leaders in the work truck industry share a key quality — they are constant learners who have found a balance between continuous improvement and innovation, which is not easy to do. One of the biggest challenges involves the right brain/left brain dilemma. As shown in Figure 2, improvement is a circular process which may deploy innovation but is practical in nature, and is intended to refine and remove waste. Innovation (Figure 1) employs discovery and creativity as problem-solving methods, resulting in a service or product.

Getting creative

Continuous learning appears to be the common denominator. Although this is a mature industry with a seemingly limited number of new processes and technologies entering the market, companies are always encountering new approaches and combinations. Also, leaders know that to gain a competitive edge, it’s important to keep developing and adopting new methods. Following are some examples.

Virtual reality

NTEA met with VRSim — which designs and develops immersive, real-time virtual reality simulations — and had the opportunity to weld in a virtual environment. The experience demonstrated how technology is changing the way we train people.

This system, developed for Lincoln Electric, looks like a welder, and allows the student to set parameters and virtually weld in multiple positions with different base materials. The helmet allows users to see the arc and hear the sound of welding. The weld and splatter are shown on-screen, and a technical quality review is given. Using this system, students can learn the basics of welding without getting splatter burns or using a lot of material. Watch the video at tinyurl.com/VRSim-LincolnElectric.

Combining elements

NTEA visited a member company that found a wire connector combining the crimp, solder and heat shrink. None of these elements alone is news, but all three combined into a single element for use on every wire joint an upfitter makes is a game-changer in terms of productivity, quality and, likely, customer satisfaction.

Sales leads

In addition to training and shop floor processes, continuous improvement and innovation are coming together in other areas of member businesses, such as finding and targeting sales leads. Identifying which company has a chassis that can use your product to sell in a specific volume range in your market area is information IHS Powered by POLK has offered the industry for years. Many companies are using such data in combination with market segment statistics to find the right new customers.

This is a short list of the many things members are learning about and innovating. If you just returned from The Work Truck Show® 2017 and Green Truck Summit, consider reviewing with your team all of the available products and technologies to see if it sparks some creativity.

Helpful resources

For questions, contact Doyle Sumrall.