By Mike Kastner, NTEA managing director

This article was published in the October 2016 edition of NTEA News.

National Highway Traffic Safety Administration (NHTSA) and Environmental Protection Agency (EPA) jointly issued the second round of greenhouse gas (GHG) and fuel reduction rules for medium- and heavy-duty trucks. These will be phased-in between 2021 and 2027.

NTEA has been deeply involved in developing the rules and their underlying statutory authority since Congress began debate in 2006 on the Energy Independence and Security Act. This Act called for NHTSA to create what would amount to a Corporate Average Fuel Economy program for trucks. It required no less than four full model years of lead time and three of regulatory stability. As the process commenced, the Obama Administration called for combined fuel efficiency rules from NHTSA and corresponding greenhouse gas reduction rules from EPA.

While the initial motivation was to regulate long-haul tractors, proposals included all trucks. NTEA was instrumental in gaining recognition — in the law and regulations — of the differences between work trucks, vocational trucks and long-haul tractors. Today, the rules distinguish between large pickups and vans, tractors, vocational trucks and, in Phase Two.

Affected vehicles

Much like with Phase One, tractors, vocational trucks, large pickups and vans are subject to Phase Two. This second round of regulations includes, for the first time, trailers used in combination with tractors.

As proposed, Phase Two vehicle and engine standards generally begin in 2021, with stringency increases in 2024 and 2027. Trailer regulations will start in 2018. Categories are defined as follows.

- Heavy-duty combination tractors. Class 7 and 8 semi-trucks that typically pull trailers are regulated under subcategories based on weight class, cab type and roof height.

- Class 2b–3 heavy-duty pickup trucks and vans. Heavy-duty vehicles with a gross vehicle weight rating (GVWR) of 8,501–10,000 pounds are classified as Class 2b motor vehicles or Class 3 for a GVWR of 10,001–14,000 pounds. Class 2b and 3 heavy-duty vehicles are referenced in these rules as HD pickups and vans. Their standards are based on a work factor attribute combining vehicle payload, towing capabilities and the presence of four-wheel drive.

- Vocational vehicles. Specialized vocational vehicles, which consist of a wide variety of truck and bus types, are regulated in three subcategories based on engine classification. They represent approximately 17 percent of fuel consumption and GHG emissions from medium- and heavy-duty vehicles.

- Trailers. This category comprises trailers used in combination with tractors, including all lengths of dry and refrigerated vans, tanks, flatbeds and container chassis hauled by low-, mid- and high-roof day and sleeper cab tractors.

- Heavy-duty engines. Phase Two rules have separate standards for vocational diesel engines, tractor engines and vocational gasoline engines

Costs and benefits of Phase Two

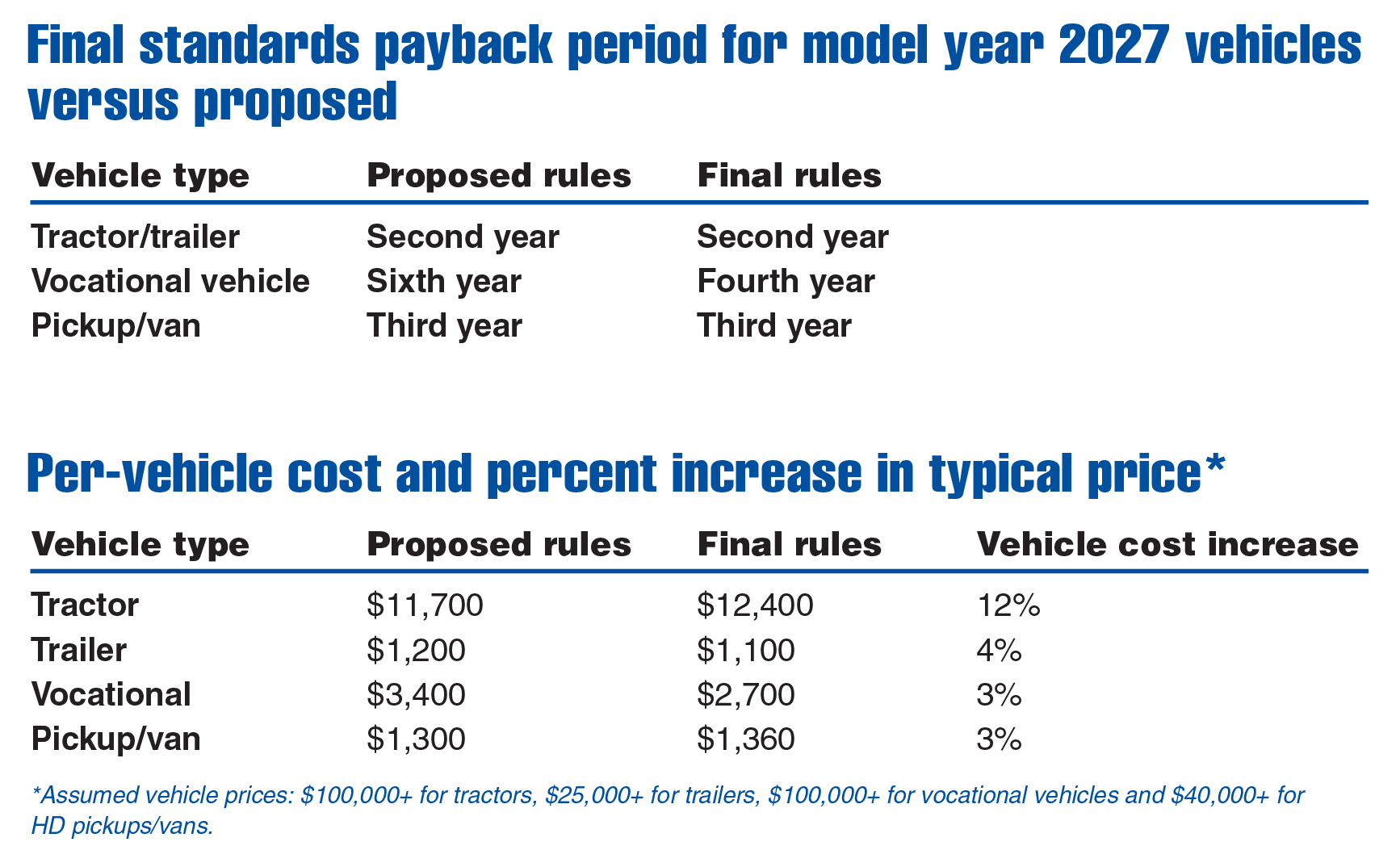

When the regulations were proposed, the cost/benefit ratios for combination tractor-trailers and large pickups and vans were viewed as reasonable. The recommended rule estimated that when fully phased in by 2027, tractor-trailers would recover additional costs associated with the regulations within two years of ownership through a fuel use reduction of 24 percent for tractors and 8 percent for the more efficient trailers. Large pickups and vans would see a 16 percent fuel use decrease with a three-year payback period. Vocational trucks, however, would be faced with a six-year payback timeframe.

NTEA surveyed vocational truck fleets and confirmed a six-year payback period was viewed negatively in relation to expenses associated with fuel efficiency gains. The survey reflected that, depending on costs, a two- to four-year payback period was generally deemed acceptable.

The Association met with regulators numerous times during Phase Two development, expressing concern over the cost/benefit ratios applicable to vocational trucks.

Final Phase Two rules set standards so that vocational trucks should experience a 24 percent fuel use reduction with cost recovery occurring in the fourth year of ownership. This lowers the cost of compliance from the proposal by some 20 percent and increases fuel efficiency by approximately 50 percent.

New technologies

In Phase One, the requirement for low rolling resistance tires was the primary change likely to be noticed by end users. Phase Two will necessitate additional effort for compliance and may include further technological enhancements as well as improved engines, transmissions and axles, weight reduction, hybrid technologies (potentially) and workday idle reduction systems.

Delegated assembly

EPA rules typically apply to engine manufacturers and OEMs. NTEA shared with EPA that many multi-stage manufacturers are capable of adding equipment that could reduce GHG emissions and increase fuel economy. As originally written, the regulations did not provide for acknowledgement of such multi-stage manufacturer actions.

The Association is pleased to report EPA recognized the value of incentivizing multi-stage manufacturer contribution to GHG and fuel use reduction. A provision has been included that would allow multi-stage manufacturers to contractually coordinate with OEMs to add parts or equipment that could contribute to the OEM compliance efforts.

Known as delegated assembly, the process will require:

- The OEM (certificate holder) to have a private contractual obligation with the secondary manufacturer to properly complete the assembly

- Record retention to demonstrate compliance

- Application of a temporary label to partially completed vehicles

- Other reasonable steps to ensure assembly is correctly completed

- Description in the certification application of how this allowance will be used

Glider kits

A glider kit is a tractor chassis with frame, front axle, interior and exterior cab, and brakes. A used/rebuilt engine and drivetrain components are added to complete the vehicle. Traditionally, several hundred such vehicles were produced per year, usually to reuse an engine and drivetrain from an otherwise damaged tractor.

Glider kit sales surged to more than 20,000 in 2015. These vehicles typically match an older pre-emissions engine with a new glider kit. As a result, EPA estimates by 2025, glider vehicles will compose about 5 percent of heavy-duty tractors on the road — but they would be responsible for approximately one-third of all NOx and PM emissions from these vehicles.

The second round of regulations will phase-out use of older engines in glider kits by 2021. In January 2017, glider vehicle builder production will be capped at the manufacturer’s highest annual production of glider kits and glider vehicles for any year from 2010–2014. Any production beyond that limit will need to use engines certified as legal for the same year the glider kit is built.

In 2018, glider vehicle engines must begin meeting emissions standards corresponding to the year of the glider vehicle. There will be a limited small business exemption allowing certain companies to produce up to 300 glider vehicles or their highest annual production volume for calendar years 2010–2014, whichever is less, with older engines.

Effective Jan. 1, 2021, the 2018 small business exemption will end and all glider vehicles must meet Phase Two GHG vehicle standards.

Learn more

For more information on Phase Two rules, contact Mike Kastner at mkastner@ntea.com. Also, the 2017 Green Truck Summit, held March 14–16 in conjunction with The Work Truck Show® 2017 in Indianapolis, Indiana, will feature sessions on how Phase One and Two regulations affect work truck industry companies.