By Doyle Sumrall, NTEA Managing Director

This article was published in the July 2017 edition of NTEA News.

Lightweighting is a consideration when designing a work truck but often not a main focus area — and it’s easy to understand why, as it isn’t typically a visible attribute. However, it can pay dividends to the owner over every mile of the vehicle’s operational life.

The Lightweight Technology Council, a working group within NTEA’s Green Truck Association (GTA) affiliate division, has facilitated the design and build of lightweight technology demonstration trucks and featured them at The Work Truck Show® 2016 and 2017.

In 2016, the display showcased an Isuzu NRR diesel Class 5 truck with an empty weight of 6,848 pounds and payload allowance of 12,652 pounds. It was equipped with 225/70R19.5F low rolling resistance, all-season/all-position tires; Alcoa’s one-piece, lightweight forged aluminum wheels with corrosion-resistant DuraBright® finish; Switch-N-Go™ Detachable Body Hoist System; and Voth aluminum truck body.

The unit represented an 880-pound curb weight savings and 1,245-pound lighter run-empty weight. These reductions offered operational benefits in lighter drive weights and, when needed, greater payload. National Renewable Energy Lab (NREL) engineers provided expert analysis of the value in terms of fuel and CO2 reductions.

In addition to lightweighting the body and wheels, other technologies such as Isuzu’s chassis data system were factored into the calculations on fuel and emissions savings over a 10-year operating period.

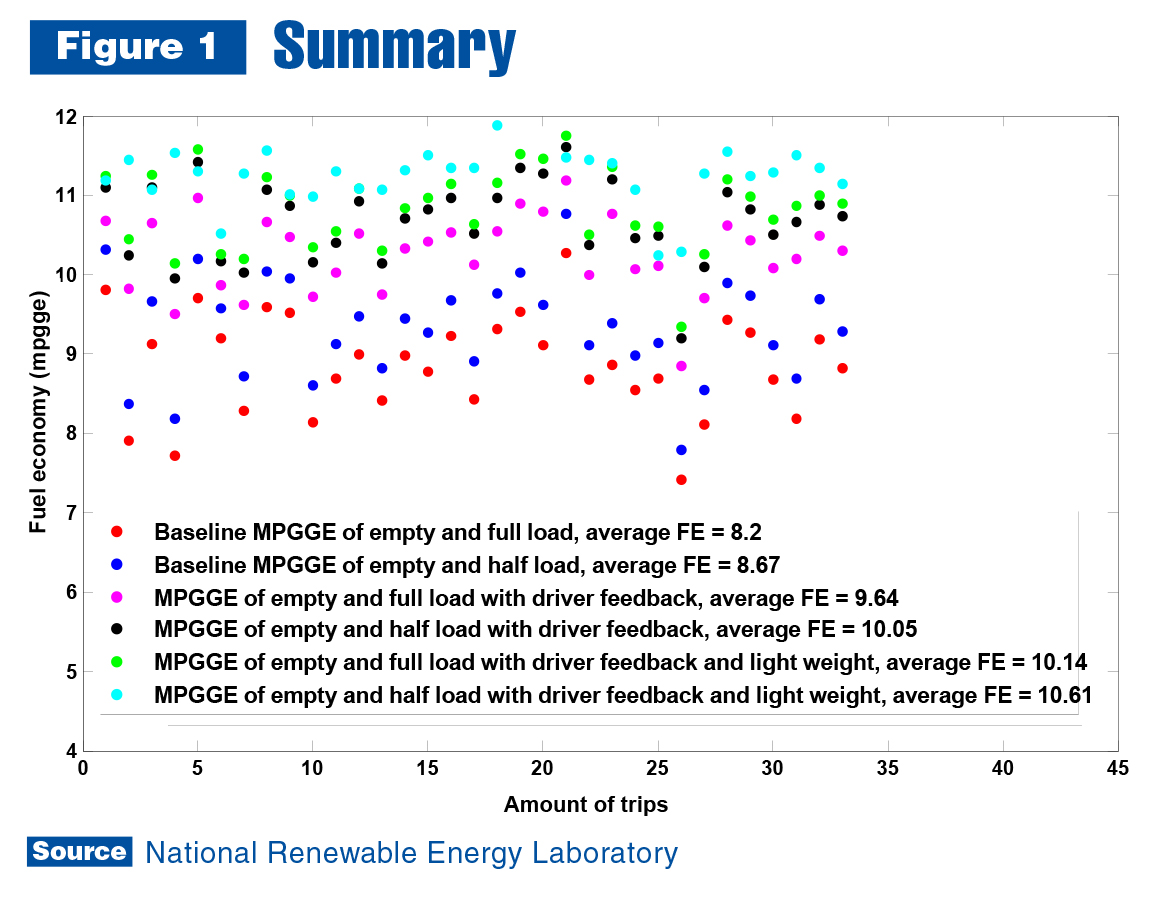

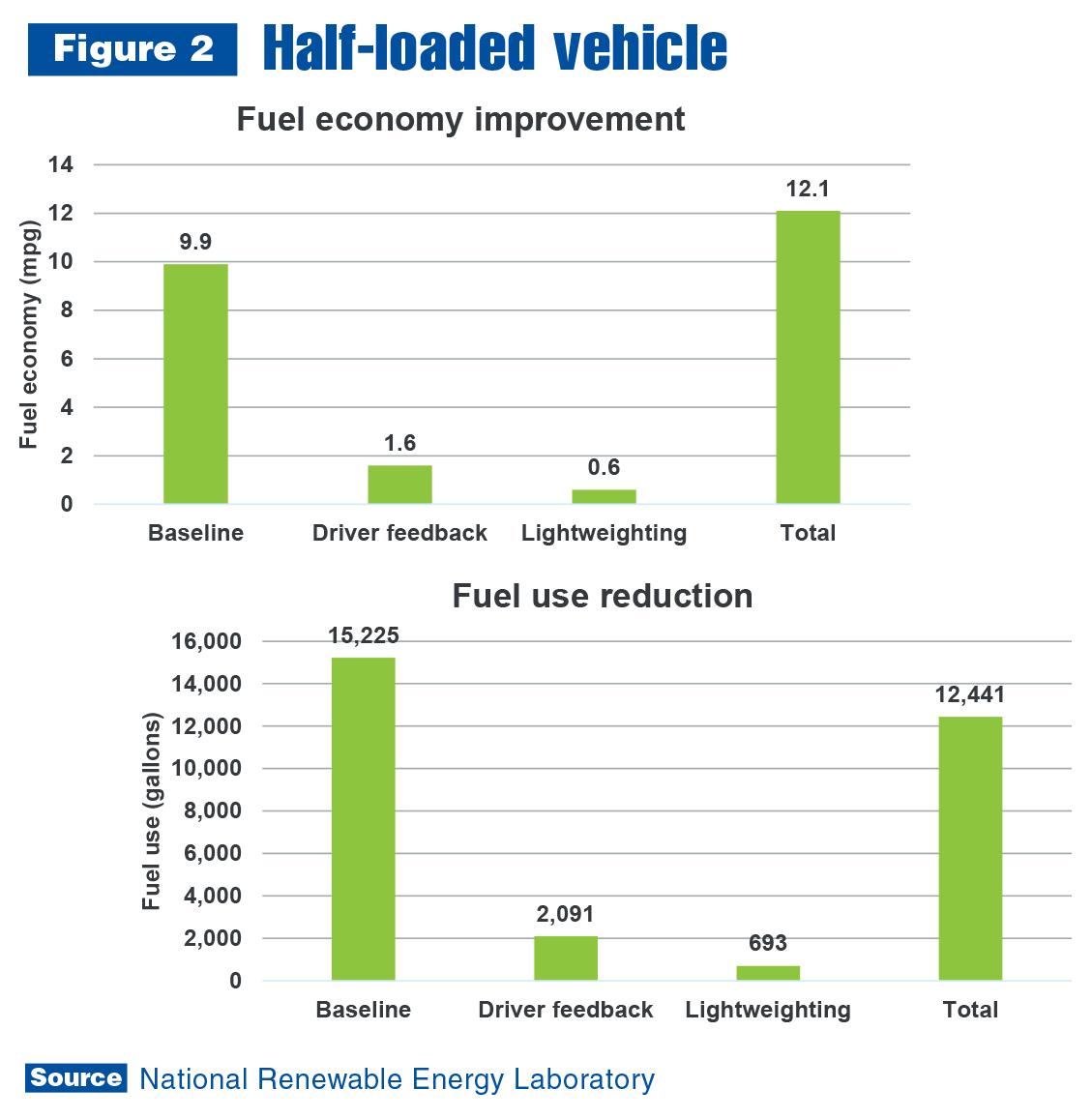

As shown in Figure 1, NREL’s analysis illustrates projected fuel mileage in various operation modes with the technologies layered in. Results reflected an improvement from 8.67 miles per gallon gasoline equivalent (MPGGE) to 10.61 MPGGE.

Over the 10-year operating span, with an assumed 15,000 miles per year, the truck will have a 23 percent improvement in fuel use and create 33.3 tons of greenhouse gas reduction.

Charitable donation

The companies that contributed to the 2016 truck decided to offer it for a one-year, no-charge lease to Habitat for Humanity and ReStore. Isuzu Commercial Truck of America Inc. is the lead contributor of the lease. Alcoa, Switch-N-Go and Voth Truck Bodies — all NTEA and GTA members — provided equipment as part of the donation.

Once in the field, it was determined a box body was needed to fit Habitat for Humanity’s operational requirements. Another NTEA member, COPANCO USA LLC, joined the donating companies, and designed and built a Switch-N-Go-compatible body.

Habitat for Humanity is using the truck to collect donations and support its operations. In partnership with Greater Indiana Clean Cities Coalition, GTA installed a datalogger on the vehicle. NREL will analyze this real-world usage data in order to validate the lightweighting and technology benefits. NREL and GTA will report the results at the 2018 Green Truck Summit, held in conjunction with The Work Truck Show, which is scheduled March 6–9, 2018, in Indianapolis, Indiana.

To learn more about the lightweighting initiative planned for 2018, visit worktruckshow.com/lightweighting. Information on GTA’s Lightweight Technology Council is available at greentruckassociation.com/technologycouncils.