By Doyle Sumrall, NTEA Managing Director

This article was published in the February 2017 edition of NTEA News.

NTEA members and National Institute of Standards and Technology (NIST) Manufacturing Extension Partnership (MEP) program centers across the country have worked together for decades. With a whole new year of possibilities ahead, it’s a good time to provide an update on the successes resulting from these efforts.

Through its MEP program, NIST is dedicated to the national issue of building a qualified manufacturing workforce. Its nationwide MEP network — with centers in all 50 states and Puerto Rico — partners with small and mid-sized manufacturers to help them create and retain jobs, increase profits, and save time and money.

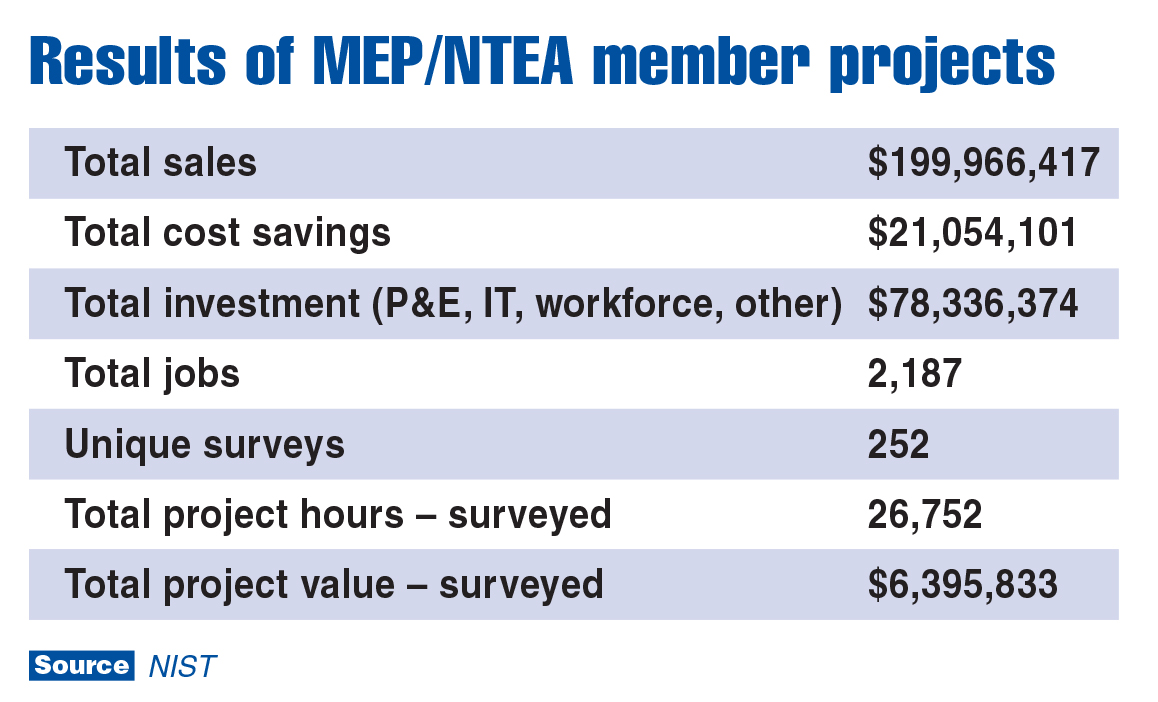

NIST MEP compiled data on the 252 projects conducted with NTEA members over the last three years, and the results are exciting (see accompanying chart). Efforts have garnered more than $21 million in cost savings in areas such as energy, labor and overhead. Increased investment in areas including plant and equipment (P&E), information technology (IT) and workforce surpassed $78 million as a result of these undertakings.

Each member company engaging an MEP center has unique needs — from strategic planning assistance to implementing 5S principles in an installation bay. Following are some challenges members presented and examples of the solutions MEP centers provided.

Redesigning

One member found a long-term partner in MEP starting from its initial redesign project which resulted in reducing product weight by 20 percent and improving fuel load. Over the years, they teamed up on numerous re-engineering projects, including a recent effort to break into a new

market space. The MEP center worked with the company on product redesigns for a bolt-on

loading ramp, a landscape dump truck and specialty trucks for construction contractors. The stronger, more economic ramp created the need for a new position and produced numerous variations, which increased sales.

Going lean

This member company needed to overhaul its manufacturing approach from a batch processing job shop to a lean enterprise. Numerous issues needed to be addressed, such as velocity and throughput, challenges meeting capacity and on-time delivery, and inventory turns. The MEP center equipped the business with information from an operational assessment. The member’s management team formulated an 18-month lean operational improvement plan. According to the chief financial officer, “Working with the MEP, we were able to completely transition from a job shop to a lean enterprise three-fold.”

Increasing efficiency

As industry growth intensified over the last several years, this member company needed to boost efficiency and develop top management in order to remain competitive and ensure continued customer satisfaction. With the MEP center’s assistance, it implemented several productivity tools as well as equipped its leaders with skills to train, motivate and foster employees to achieve greater output. The My-Tyme® Success Planner helped managers take charge of their personal productivity. Not only did participants improve their understanding of themselves, they were also better equipped to more efficiently communicate with team members.

Cultural changes

This member company initially partnered with MEP for training on lean and 5S principles. After working together, their partnership expanded to ensure a company-wide culture change to lean, 5S and continuous improvement. Today, it is hard to tell where the MEP center ends and the company starts because MEP spends one day every other week working side-by-side with the company’s team. Beyond training in lean, value stream mapping and leadership, the MEP partner is a key member of a cross-functional continuous improvement team that is making great strides by reducing waste, increasing capacity and decreasing job-related stress.

Training

Aluminum is not an easy material to weld, and this company couldn’t afford extensive, hands-on training with such a temperamental material. A trained, efficient workforce in its smaller, rural area was not easy to acquire and retain. MEP’s solution involved partnering with local community colleges to provide necessary training. In many instances, the newly skilled employee stays in town, building on the industry’s qualified workforce.

Quality

This NTEA member markets its products through various distribution channels. It was committed to establishing an ISO 9001 system from day one, and decided to bring in MEP for assistance. MEP team members have more than 40 years of collective experience with ISO quality standards. These experts walked the company through all of the steps involved in preparing the documentation essential to certification. In addition to helping write the quality manual and supporting documents, MEP provided auditor training and management reviews. The approach was efficient, generating only the documentation critical to certification and avoiding unnecessary, extra work.

Learn more

There are more related success stories covering a variety of challenges and opportunities. The common thread is partnering with local MEPs to improve productivity, sales, operational environments and profit.

Since 1988, MEP has worked with more than 86,000 manufacturers, producing $96.4 billion in sales, $15.7 billion in cost savings and more than 797,994 jobs. For additional information, visit nist.gov/mep.